To Laugh or Not to Laugh, That is the Question.

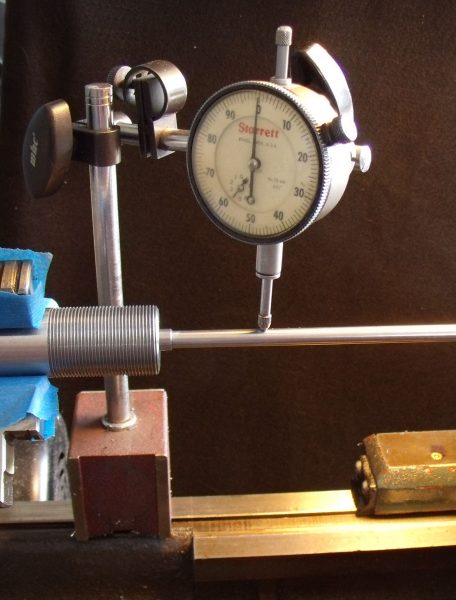

Dialing in a barrel.

You hear some things on the phone that really make you laugh when you rent tools. They might not be funny to the average tool user but maybe we need to share them to clear up some misunderstandings?

One of my favorites is, “That barrel has been in the lathe forever waiting for the reamer.”

We ship over 90% of orders withing 24 hours of receiving them. When we cannot ship right away we keep the back order list in front of us as tools return from rental and fill the orders ASAP. As for having the barrel in the lathe, why set up a barrel before you have all the tools and parts on hand to finish the job. But, if you did start the job and then parts or tools interfere with completion, who cares. Pull the job from the lathe if you need it for another project. Any gunsmith worth his salt can dial in a barrel in a few minutes. I know this because I have been barreling guns for over 35 years. Is it convenient? No, but you have to do what makes money.

Next on the all time favorites list is, “I’ve been waiting for the right size pilot.” First, it’s the customers responsibility to tell us when ordering what size pilot they want. We have a comment box at check out so you can make such requests. Second, you can make a pilot to fit your barrel, the reamer makers do not have a patent on pilot making, and it requires no special magic, you never read about Merlin or Harry Potter the tool maker. For speed, use brass or bronze to make pilots.

“This reamer chatters…” The first thing that should be obvious is that nearly all of our reamers have been used by other competent and experienced gunsmiths with no complaint. Chatter is caused mainly by a few variables. #1 is pilot fit to the bore, if it is within .001″ on diameter it will likely not chatter. The temper and/or chemistry of the barrel steel can affect chatter. Cutting speed, if it chatters you can normally stop it by changing the RPMs. Slower speed will often stop chatter, of course sometimes it may be faster that works. (Do not Exceed the Reamer Makers recommended speeds) If you would like to learn more about how to barrel and chamber, check this out.

You can stop chatter by using the wax paper or cleaning patch trick. Simply wrap the throat/shoulder area of the reamer with two or three wraps of wax paper torn in 1/2″ strips. Others use a cleaning patch, slit the patch in the middle just enough so it will fit over the pilot. Let it hang on the neck and shoulder area of the reamer. In both methods continue to use plenty of quality cutting oil. This combined with slow RPMs has never failed me.

Then there is always Ackley, its a short ‘a’ sound. P.O. Ackley is a hero of ours around here.

We have a whole section just for Ackley reamers.

Book Cover, P.O. Ackley, America’s Gunsmith

Gunsmithing Student Handbook Series #1