Jump to the Subject you’re interested in:

Ordering | Communication | Dimensions | Locating Tools on the Site | How To: | Sharp Tools | Rental Agreement

Am I Buying? | Too lazy to Read

Ordering

How long is the Rental Term?

You have seven (7) days from the time it arrives at your address to use the tool. As soon as you are finished with the tool. Please return it on time so that it will be available for the next renter.

What all is included?

Everything is ala-carte. You get to pick and choose only the tools and items that you want, this saves everyone money!

Am I Buying or Renting?

Note the side bars both right and left on each page of they site the will state “RENTAL” or “For SALE” to help you be certain.

You can check the heading for the section of the web site as well, all for sale items are listed under the “NON-Rental Store” part of the web site.

You already charged my card?

When you order from this web site the cart will automatically charge your credit card for the rental and shipping at the time that you place the order. If you have questions about our rental policy; Click Here to read the rental agreement.

Overnight Shipping

When you choose this method of shipping: We cannot promise it will get into the shipping system if the order comes in after 1 PM Mountain Time. No shipper currently guarantees overnight delivery, it is simply the fastest delivery method they offer. We ship UPS overnight in most cases. You still have 7 days to use the tool, so we expect to see the tool back in about 14 days. If the item you order costs more to ship than the listed cart fee, we will contact you to see what you prefer to do, the rate listed is for a UPS Envelope, so if the item will not fit the envelope expect a call or email. We are closed on Saturday and Sunday.

Standard Shipping

Standard shipping is USPS, Priority Mail.

When should I order?

Do not rent if you are not ready for the tool. Our focus is on getting tools out to clients as fast as possible.

Ordering on your cell phone?

This is the least efficient way to order. This web site is optimized for mobile devices, but it is our experience that more errors occur when entering your order on a phone. Please take a little time to double check the details before your order.

Who pays the return shipping and insurance?

The client agrees to pay the return shipping. Be sure to insure the package as you are responsible for the tools until we receive them. We do not supply a return label.

Package the items you are returning with reasonable padding so they do not rip through the outer package. We use care in shipping the products to you, please emulated that same care when shipping tools back.

Why don’t you supply a return shipping label?

In many parts of the country it may be difficult to use a specific shipper, so we leave it up to the client to choose the return shipping method to keep the process as easy and convenient as possible.

You shipped it to the wrong address?

You enter your billing and shipping address when you place the order. If you use auto-fill read what is placed in the order form. It is totally your responsibility to make sure addresses are correct.

Return Tools to:

4D Reamer Rentals LTD

301 Thelma Dr., Suite 202

Casper, WY 82609

Do you sell Reamers?

Yes, they are strictly on a special order basis, we can often supply common calibers in a week or two, headspace gauges too. Email us with your requests.

We do stock most standard gauges for sale, Click Here.

Do you Ship outside the U.S.?

NO. Sorry, we do not ship outside the U.S.

I did not use the tool, can I have a refund?

When you place an order for a tool, you are purchasing the time to use it. Since the tool is out of inventory for your order we cannot use that tools to serve another client. You should only order tools you know you really need. More details about renting tools: Click Here.

I’m scared to death to rent tools!

No need to be afraid, we have been doing this for a very long time. In the average year only about 2% of the tools are either lost or damaged due to accidents, negligence or shipping problems. So it’s not a big problem. If that does not relieve your fears about the possible costs, then check out our Rental Protection Plan. You can control the cost. Always insure packages coming back to us to protect yourself.

Communication

Requests/Questions

Please always use your invoice # when communicating. We ship large numbers of orders on a daily basis, it saves tons of time if you supply the precise name or business name you ordered under and the invoice #.

I left a message…

Our phone system does not accept messages; intentionally.

Email is always the best way to communicate as we can respond at any hour. Order volume is high we work long hours shipping internet and fax orders. We want to get the tools out the door as soon as possible, this is what clients tell us is important to them. Fax # is 406-890-6341 Email: reamers@4drentals.com

If your message is, “Call Me” you will be very low priority. Again, Email is best!

I thought sending the same email 12 times would be helpful!

Once you have sent a request for assistance we will get to you as quickly as we can.

If we see that you are sending the same message over and over again. We do wait until messages stop coming in before responding.

We always prioritize shipping first, then emails.

Do you send Email notification when the order ships?

Yes, if you provided a legitimate email address when ordering the tracking info is sent to your address automatically. The return address is from the USPS unless you requested another shipping method. Please check your spam filter before you ask for tracking info.

When you see that your order reads as “Completed” on the web site or in an email that only means that the credit card processor completed the transaction. You will receive a separate e-mail with tracking information when the package ships, this is why you should supply a correct email address.

We have seen a lot of email addresses with added letters or figures that are obviously placed there to cause email failure. When you do this do not ask why you were not notified… Should be self explanatory.

Shipping Delays.

About 98% of our orders ship within 24 hours. Those that do not are placed in our Back-Order log. Every day when we receive mail we check the returned tools against the back orders. We will not forget your order, our business relies upon getting you the tools you ordered as soon as we possibly can. If your order is delayed you will always have 7 days with the rental tool in your hands, ship it back as soon as you are finished.

Overnight Shipping is no longer guaranteed by FedEx or UPS.

Getting the most out of our services.

We are a super friendly company and we want you, our clients, to have all the success in the world. We will always work with you when you have concerns. Momma taught us to use honey instead of vinegar… you will find that works pretty well for you too when we communicate. In short, Please, Thank you and a smile go a very long way. We look forward to working with you.

We will never!

We will never send you an email asking you to update your account. Your account is managed totally on the web site when you are logged in and placing orders. We do not sell or share account information with anyone. PERIOD.

Locating Tools on the Site

Finding any tool?

On the home page of this site there is a search window right in the center, first thing you normally see. Type in the caliber or name you are looking for. If you do not see what you want in the list provided then change your search terms. Many calibers go by more than one name.

At the top over every page you will find a basic menu that can take you to any subcategory on the site for direct viewing of listings. Dig in, its pretty likely that it’s there, we stock more tools than any company in the rental business.

Where are the Headspace Gauges?

Headspace gauges are rented by selecting the combination of reamers and/or gauges you need from appropriate buttons when you’re looking at any specific caliber reamer. We aim to keep it simple! Don’t know what a headspace gauge is? Click Here.

Do you send me a selection of pilots with the reamer?

As stated in the Rental Agreement; We do have a limited stock of bushings and it is your responsibility to tell us what diameter you need. Groove diameter is not the same as bore diameter. Bore diameter is across the lands (the smallest diameter). Bushings must work with your bore diameter.

No we do not send you an assortment, if you want extra pilots you can order them, Click Here.

Dimensions

Can you send me a print?

It’s not as easy as you think. Reamer makers provide a standard print for the chamber reamers they make. Prints have tolerances that are extrapolated by the reamer maker from SAAMI standards. So a reamer can be within tolerance and not exactly match the print. Prints provided by reamer makers are generic in that sense. We do not have prints specific to any tool. All we have are either SAAMI prints or prints given us by the reamer maker. Imagine you had over 2000 reamers to take care of along with more than twice that many gauges and hundreds of other tools that we rent out. Just sayin…

What is the Neck diameter and/or Freebore?

Our reamers are standard for caliber unless otherwise stated in the price list or on the web site. Otherwise the throat and neck will be standard for caliber. Nobody reinvents the gun industry by changing such details. To paraphrase a P.O. Ackley guote, “To revolutionize the gun industry, just raise the sights on the keyboard.” Reamer makers normally apply standard for caliber freebore length, i.e. that means if the designer of a wildcat does not specify a throat, the reamer maker will give it what they would put on the factory equivalent. Imagine that 25 people a day asked you this…

How to:

“Gunsmith Tools, Cutters & Gauges” is a book assembled by the leaders in the industry explaining common gunsmith tools and their function. We strongly suggest that you read the book: Click here to order. For a discount use coupon code: primeme and save $5 just because you took the time to read this FAQ.

Which way do I turn this thing?!?

All reamers that 4D offers for rental are right hand or clock-wise cutting.

In other words, all reamers should be turning to the right. If the barrel is in a lathe the barrel will run in normal forward direction or counter clock-wise.

We have some videos prepared that help explain the use of gunsmithing tools, click here to see what we have.

Why is this important?

Because running the tool backwards will damage it. Damage will likely require a professional resharpening, your deposit would then be forfeit to cover that expense. Not only that but it will take about a hundred years to ream a chamber in reverse and the quality of the chamber will be very poor.

Do I need to use a lubricant when reaming?

Absolutely, we recommend Brownell’s Do-Drill, Conoco makes a cutting oil called “Spectrum” These are two oils that will work well, there are others. We sell Tap Magic which will work to ream a chamber.

How do I make a chamber cast?

We recommend CERROSAFE® casting metal, it is a low temperature metal designed for making precision casts of cavities. It’s properties are well known in the gun industry and reamer makers as well as gunsmiths will recognize the brand name. Simply follow the link above for instructions on use.

What is the difference between Solid and Floating Pilot?

Solid pilots are integral to the reamer, they do not move and are ground to the common SAAMI dimension for the given caliber. Floating pilots or bushing pilots are a precise slip fit to the pilot area of the reamer, they can be interchanged to allow for the best possible fit to the bore. All reamers come with STANDARD size pilots. If you are ordering non-standard pilots there is a comment box at check our for such details.

Which is better? That is a subject of ongoing debate in the gun trade, about 50% of clients prefer one or the other. Floating pilots have the advantage of versatility, Solid pilots do not run the risk of stacking tolerances. Both types of pilots will produce excellent chambers.

Click here to read a full article on this subject.

We reserve the right to upgrade your order at no charge.

Rental fees for removable (floating pilot) reamers are more $ than for solid pilot. In the event that substantial delay will result if we hold your order for a solid pilot reamer, we reserve the right to upgrade the reamer to floating pilot at no charge. This is to insure the fastest possible service on your order.

How do I use Ackley Improved Headspace Gauges?

In rimless bottleneck cases you will use an Ackley ‘Go’ gauge. The ‘Go’ gauge for the parent cartridge will become the ‘No-Go’ Gauge. Why does this work?

Ackley was pretty smart, he realized that if he set up the “Improved” chamber shorter than the factory chamber that you would be able to fire factory ammo. Because the brass is slightly crushed by the neck/shoulder junction of the new shorter chamber it is held tight against the bolt face for firing. That is why you must set the barrel back when rechambering for a rimless bottle necked cases in Ackley Improved configuration.

Click here for more complete info on Ackley headspace.

Why no Ackley gauge for rimmed or belted cases?

Simple, these cases are headspaced on the rim or the belt, so the shape of the chamber has no affect on headspace. The case is trapped between the boltface and the forward edge of the rim or belt, so when you fire the cartridge it simply forms to the new shape of the chamber.

I think you sent me the wrong reamer?

I reamed a piece of nylon with it and my ammo won’t fit?

That’s because Nylon is not steel, it springs and moves away from the reamer.

It’s too long?

Sometimes the reamer maker uses a long reamer blank for a short cartridge, it’s not a

problem. The length of the reamer blank has no correlation to the chamber length;

headspace gauges are used to establish the actual depth of the chamber.

Sharp Tools

I did not get a sharp reamer?

Highly unlikely as we take exceptional care to see that they are in good shape. A couple of things that may make you think the reamer is dull:

- Barrel made of much harder alloy than normal or heat treated to an abnormal hardness.

- Semi-Auto pistol barrels are often harder to deal with wear of the locking system.

- Chrome washed bore or chamber, High Speed steel reamers will not cut Chrome!

- Working by hand

- Turning the reamer the wrong direction (don’t laugh) clockwise is correct.

- Pilot too large for your bore, don’t force it.

- No cutting fluid, cutting oil is necessary!

If you feel the reamer is dull contact us immediately. Email is best for such conversations. We will help you resolve the issue in as short a time and as cost effectively as possible for all concerned.

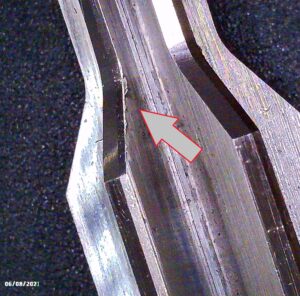

We touch more reamers in a week than most gunsmiths handle in a year. We know the difference between Wear, Damage and Chip-Weld. Above is an example of Chip-Weld:

Chip-Weld is caused by three major factors.

1. Sticky/Soft barrel blanks (you cannot control this good cutting fluid will help).

2. Quality of cutting oil (buy better cutting oil).

3. Pushing the reamer too hard (ease off on the feed rate)

Above is a reamer that is damaged. Note the cutting edge is rolled over and dull, very different than chip-weld. This damage is well beyond normal wear. It’s caused by either misuse of the tool or a hard barrel, either way the end user is responsible.

Above is a reamer that is damaged. Note the cutting edge is rolled over and dull, very different than chip-weld. This damage is well beyond normal wear. It’s caused by either misuse of the tool or a hard barrel, either way the end user is responsible.

Should I sharpen the reamer?

NO. We inspect the reamers it assure you are getting a sharp tool. Much of the damage we see to reamers comes from incorrect stoning or sharpening of the reamer. The client is responsible for the cost of repairs for such damage. We have a video on this subject on another page, click here.

Shogun Choke Tools, I think its dull?

We inspect these tools before they go out. If we suspect a problem or one is reported we cut a test barrel here in our shop. 99.999% of the time the tools are working correctly when inspected. The most common error we hear from clients, is trying to use these tools without first removing the fixed choke in the barrel, this is absolutely necessary. Fixed chokes are removed either by shortening the barrel to reach the cylinder bore dimension of the barrel, or remove the choke with an adjustable reamer.

Bushings should be a slip fit to the bore. Any resistance will make the tools harder to use and can damage the tools or your barrel. NEVER MODIFY the bushings, if you need a non-standard dimension make your own bushing, you are not allowed to modify our tools.

These tools are very large in diameter and are cutting on a huge surface area. Cutting oil and power is required. If you do not have a lathe or some other reasonable way to power the tools we do not recommend using them by hand. Ideal RPM for the reamer is about 100, absolute maximum would be 200 RPMs. Turning the reamer too fast or without enough lubrication will damage the tool.

Naturally, the tap should be used with a large tap handle by hand.

These are High Speed Steel tools. They are not intended to cut chrome washed bores. Chrome will destroy the tool and you will pay for its repair. Know what you are working with!

Click Here for Shotgun tools. Click Here for Shotgun Choke Interchangeability.

Too Lazy to Read… The Rental Agreement still applies!

Am I Buying or Renting this item?

Note in the screenshot above, the words “FOR SALE” run along the side bars.

If the item you are viewing is a rental the sidebar will say “RENTALS”.

Many People believe “The customer is always right.”

This is not the complete saying. “The customer is always right, in matters of taste.” When it comes the business operations, policies or services the business owner is the expert.

Rental Agreement = Rental Agreement, Click Here to Read the Full Text you are agreeing to when ordering.

YOUR ORDERING FROM THIS WEBSITE IS EXPRESSLY CONDITIONED UPON YOUR ACCEPTING AND AGREEING TO THESE TERMS & CONDITIONS; PLEASE READ THEM BEFORE ORDERING FROM THIS WEBSITE. BY ORDERING FROM THIS WEBSITE, YOU ACKNOWLEDGE YOUR ASSENT TO THESE TERMS & CONDITIONS WITHOUT LIMITATION OR QUALIFICATION. Click Here to read the Rental Agreement.