Forster Products, Reloading Fall Bash

In early September 2022 Forster Products staff and owners put on an event for Distributors of their products along with other industry contacts. The facility for the event was “The Site, Firearms Training Center” in Mount Carrol, IL. Lead Instructors: Jim Kauber & Lara Spanic were great to work with and kept us all focused on safety as well as learning and having fun. I should mention that “The Site” is probably the nicest kept shooting facility I have ever been on.

Ashley Taylor of Global Shop Solutions is learning about the Co-Ax Press from Rich Machholz

Forster Pro-Staff Support members in attendance were: Rich Machholz, Kelly Bachand, Lara Spanic and Randy Bimson

Forster Support: Scott Kempel, Ryan Benning, Vince Alber, David Smith

Course description: Provide attendees with practical, hands-on capability to build match grade ammunition specific to their individual long range or hunting rifles. In conjunction with Forster Reloading Products, the class focused entirely on what’s essential when building precision rifle ammunition. Forster Products personnel and Pro-staff members demonstrated and provided individual guidance on the proper setup and use of the Co-ax® press, dies, case prep, case inspection and measuring tools. Other manufacture’s match grade reloading products were also demonstrated and used.

Attendees had wide ranging experience with reloading which made the class a lot of fun. Some had never reloaded at all, others had a lifetime of experience, all were there to share and learn.

The first day consisted of classroom demonstrations and reloading of match ammunition. Jim Kauber introduced us to the facility and the expectations for the class. He is a great guy and runs The Site, he gave the safety briefing and introduced everyone. Jim was our main range officer as well. He then turned us over to the Forster team to do some reloading for our rifles.

Case prep station.

Case prep, priming, charging powder and seating bullets were the order of the day. Hodgdon supplied powder and Sierra brought the bullets. The newbees were given all the personal attention they needed to learn and be successful. Those who were more experienced took their time and played with all the tools available, for the experience with new tools.

Co-Ax Primer Seater

There were a couple of different ways to prime cases on hand. The Co-Ax press has it’s built in priming station on the top of the press. Which is easy to use and very reliable. The Co-Ax Primer Seater is an auto feed bench mounted priming tool. It was highly effective and gave uniform seating depth of primers. Most reloaders will tell you that primer seating can have a huge effect on accuracy, so a tool that is repeatable and delivers uniform results is very useful.

I used the Bench Rest Ultra Micrometer Seater Die from Forster to seat my bullets. I have long been a proponent on inline bullet seaters and even manufactured and sold my own version of these type of bullet seaters once upon a time. Inline seaters are much more accurate that conventional seating dies because the do not force a bullet into the case mouth at an angle. Instead the hold the bullet straight in line with the case for seating, thus the term inline bullet seater. Forster makes a standard inline seater and the Micrometer version. Both do an excellent job. Personally I love the micrometer because of the fast adjustment for planned bullet seating depth.

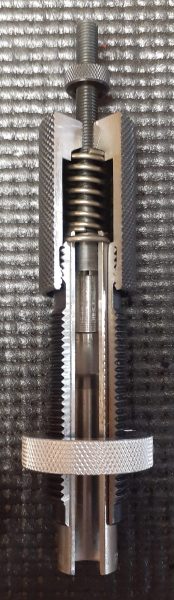

Below at right is a cutaway of the Forster Bench Rest Seater Die, allowing you to see the inner workings of the die. The difference between this die and the micrometer versions is the seating stem. Given the choice I would use the micrometer version every time, but I love accurate tools. Some reloaders are on a budget and the added convenience is just not worth the extra money to them. The standard die produces equal quality ammo its just slightly slower to adjust the seating depth.

Forster Seating Die

If you have never used a Co-Ax reloading press from Forster you are missing out on a unique pleasure. I personally have five different reloading presses mounted on my loading bench. This was my first chance to try loading with the Co-Ax. I loved it, the unique shell holder system and to leverage of the press were great, I think I need a new press. The priming station on the top of the press is convenient and easier to use the many of the “O” type presses I have used. It’s a little funny to have been reloading for forty years and find out that a tool you have always known of is actually better to work with than you every guessed.

Once we had ammo loaded it was time to go to the hundred yard range and see how thing shot. Naturally we were interested in getting a base line for accuracy. The idea to the class was to head back the the loading bench with once fired cases and see what we could do to improve on our loads. Everyone brought a rifle of their own to test and shoot, so there was a broad selection of calibers on hand. Most were bolt guns but there was also an M1A on the line.

Tools like the Neck Tension Gauges and the Datum Dial from Forster were used to make measurements and improve the quality of the second round of reloading. Bullet seating measurements were taught for those who did not have that experience. All these pieces of information were combined to create better ammo. The next trip to the range was at 200 yards and results proved that paying attention to details did improve accuracy. For the new to reloading attendees this was an eye opening class and converted them to the reloading fraternity for life. For the more experienced attendees it was a great opportunity to network and try some new tools. Mixing business and pleasure is always profitable, one way or another.

The Folks at Forster were great hosts and are excited about the new products they are developing now.

On the range with the reloading class.