To Gauge or not to Gauge? Liability is the question. Part II

Part II

The cheapest insurance you will ever buy, Professional headspace gauges.

If there are times when using brass to gauge headspace is OK then there must be times when it’s a bad idea.

- High intensity cartridges

- Wildcat cartridges

- Ackley Improved cartridges

High intensity cartridges run from 47,000 PSI to 65,000 PSI. A high intensity cartridge with a little headspace can cause all kinds of problems. Excess headspace will allow brass to stretch at the web just ahead of the solid case head. This will lead to case head separations in as few as one loading depending on the dimensions of the chamber in question, and the dimensions of the brass in question. An astute reloader will set his dies to minimize case stretch, but you cannot rely on the reloader to understand this issue. I do recommend sharing information with your client to educate them on proper loading techniques.

If you or your client love to ride the wild edge of velocity and pressure (and we all do to some degree) then keeping headspace to a minimum is an absolute necessity. When a cartridge is fired and excess headspace is present, or in other words, a gap between the casehead and the bolt face, the action will take a pounding with every shot. On top of that, a hot rodding reloader is pounding the gun even harder, in some cases they are approaching a proof load in terms of pressure with every shot. You’re not responsible for what they do, but you can still protect yourself from liability by keeping headspace to zero.

Here he goes talking out both sides of his mouth…

With wildcat cartridges using brass for headspace is a bad idea. As mentioned before brass can vary widely in quality and dimensions.

If the wildcat is of your own design, then make a gauge or have one made so that you’re always working to known dimensions. If it’s an existing wildcat then use the proper gauge. Over the years too many smiths have just done whatever they want for headspace. The problem is pervasive enough that the reloading die manufacturers now ask for a chamber print when they sell wildcat dies; even for old time well known wildcats.

This brings us to Ackley Improved cartridges. There are no simpler cartridges to headspace correctly and yet they are the most abused and trashed chambering jobs of all. Maybe because the system is so simple, people try to make it more difficult. Also because they are so popular they have more opportunity for error.

Rimmed Ackley cartridges use the gauges from the parent cartridge. No other gauge is needed. Why? Because these gauges work on the rim of the case, not the shoulder, so the shape of the body is almost immaterial. Belted cases also work this way.

Rimless, semi-rimless, and rebated cases for Ackley Improved designs all use an Ackley gauge that is .004” shorter than the standard go gauge for caliber. The go gauge from the factory parent case becomes the no-go for the Ackley chamber. This insures that the factory cartridge can be fired in the chamber safely, thus fireforming to the “improved” shape.

An Ackley gauge being .004” shorter in length causes the junction of the neck and shoulder to be the headspace point for the factory case in the Ackley chamber. This method means that the factory case is pinched or trapped between the bolt face and the chamber so tightly that it can then be fired safely. When fired the brass balloons out to the new Ackley type chamber.

Even though the shoulder angle is change, the gauges provide the same chamber length.

To further complicate the gauge situation for Ackley cartridges, some of the reamer makers now offer Ackley gauges with 40 degree shoulders, instead of the traditional design that had the original factory shoulder angle. The only thing that this should change is the way that the gauge interacts with the chamber. Otherwise the measurements should all work out the same. If your confused then a matched set of gauges for caliber will alleviate any concerns.

Standards and Tolerances…

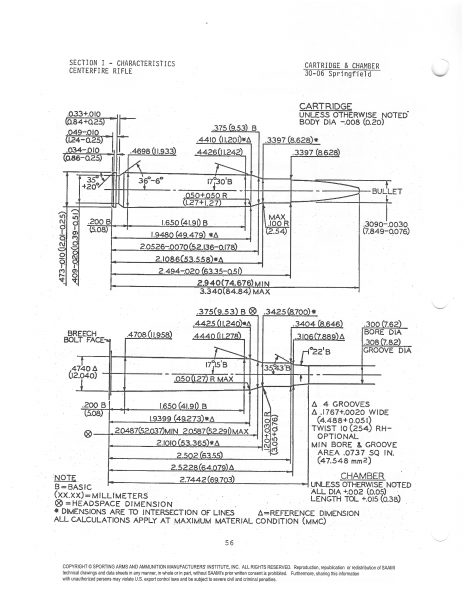

The firearms industry utilizes voluntary standards. SAAMI is the library and registry for these standards. Utilize the data SAAMI provides, it is invaluable. SAAMI does not register standards for wildcats. Only members of SAAMI can submit cartridges for standardization. However, they will accept prints of your wildcats as a record and this could potentially save your bacon some day if you plan to market a cartridge actively.

The voluntary standards available from SAAMI protect us all from liability if we stay within them. The other option would be to have a government agency take over standards. If you think that sounds like a bad idea then you understand what prompted me to write this article. Gauges are your best defense against liability issues, so whenever possible; use them.

You can download the standards from SAAMI at: http://www.saami.org/specifications_and_information/index.cfm

SAAMI specifications for chamber and ammunition.

When you read the specifications for a particular cartridge you will note that there are tolerances called out for cartridge and chambers. Take the time to look them over, become aware of the fact that there are acceptable standards already established. There is no reason for the gunsmith to fly by the seat of his pants. Even when working with a wildcat, many of the SAAMI standards for the parent case will still apply. Once you understand these tolerances you will be better able to diagnose problems with chambers and headspace much faster.

Now go forth and measure thy success.